About BINIQBAL

.gif)

Who we are ?

It was all about putting more than 35 years of family business experience in Chemical engraving, the market's challenging situation of technology development, ever-changing customer's requirements and last but not least 15 years of personal hands-on experience of Chemical and Digital engraving put together as a result, founded Biniqbal Gravure Services.

Pantograph (1st Generation)

(Era of significant vacuum of skilled Pentograph artist)

Started in 1955 with Pantography For Textile roller print and Embossing Cylinder

Chemical Engraving (1st & 2nd Generation)

(Textile and Embosing Roll)

1965 Upgraded to Chemical Engraving using Film Exposing method For Roller and Embosing Cylinder

Chemical Engraving (1st & 2nd Generation)

(Roto Gravure)

1982 Started Chemical Engraving for Roto Gravure printing cylinder

Chemical Engraving (3rd Generation)

(Roto Gravure and Roller Printing)

In 1997 adopted the next level of chemical engraving with Digital Film Processing method

Digital Engraving (3rd Generation)

2005 Upgraded to Digital Engraving using chinese Engraving machines and Plating line for Roto Gravure Cylinders

Biniqbal Gravure Services

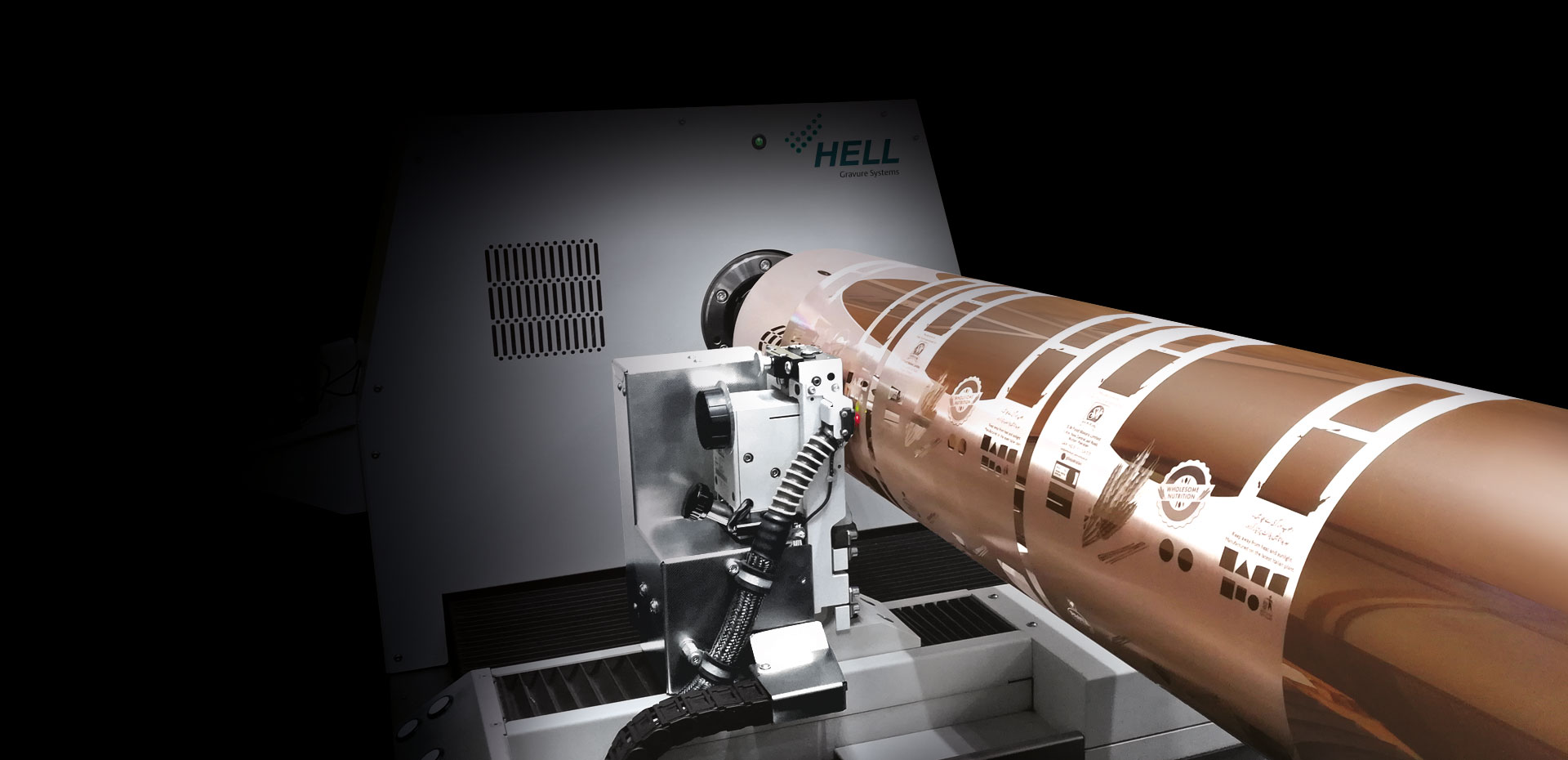

2015 established Biniqbal Gravure Services with the state of art German Technology leader Hell Gravure Systems.

HelioKlischograph K2

Remarkable addition in Biniqbal Fleet of Hell K2 Engraving machine

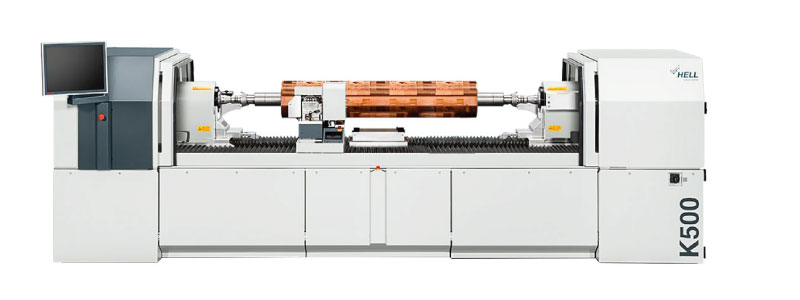

HelioKlischograph K500

Added another state of the art Gravure Machine Hell K500 with 8K Speed to Biniqbal Fleet

Applications

Flexible Packaging

At BinIqbal we always try to enhance designer creativity, special treatment for vector(small text) and as well as halftone (images) creates sharp and appealing results.

Ink consumption

Keeping in mind the abnormal hikes in inks and solvent prices which created tough competitions, to overcome this critical challenge.

Our experienced team has developed special gradations to save inks especially white color, working close with printer and ink manufacturers we can reduce ink and solvent costs up to 25 to 30%.

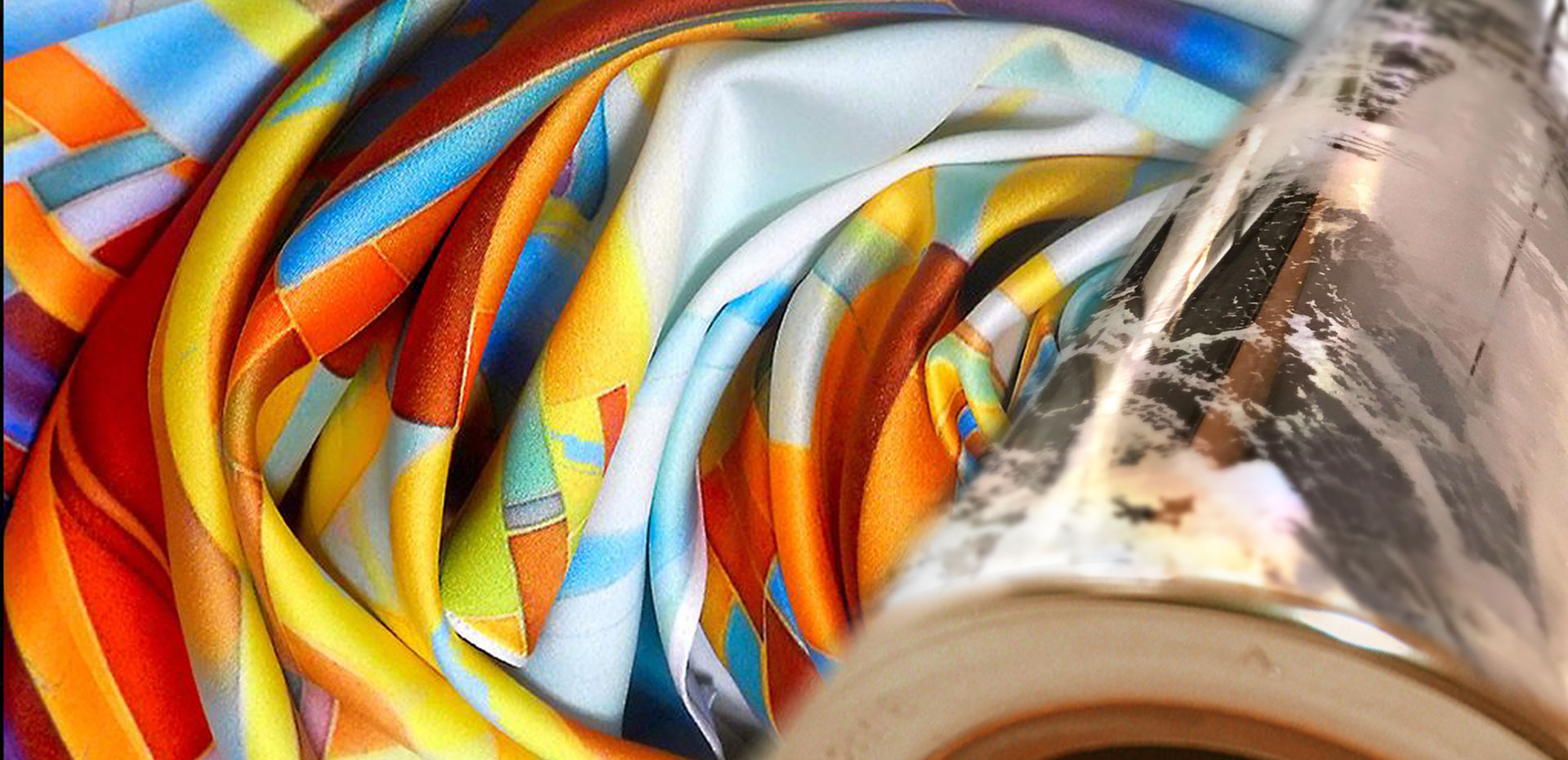

Sublimation Printing

Off course, applying early chemical engraving experience on direct cloth printing helps BinIqbal to create a special impact for Sublimation printing developing detailed separations.

Using combinations of Process, Spot, and Pantone colors the obvious output comes with an extended gamut having rich vibrancy.

Decor

When it comes to the solution for the Decor industry, cylinder sizes do matter.

In BinIqbal we can produce cylinders length up to 1600mm having a circumference of 1500mm which facilitate the target market of Decorative Furniture and Wallpapers.

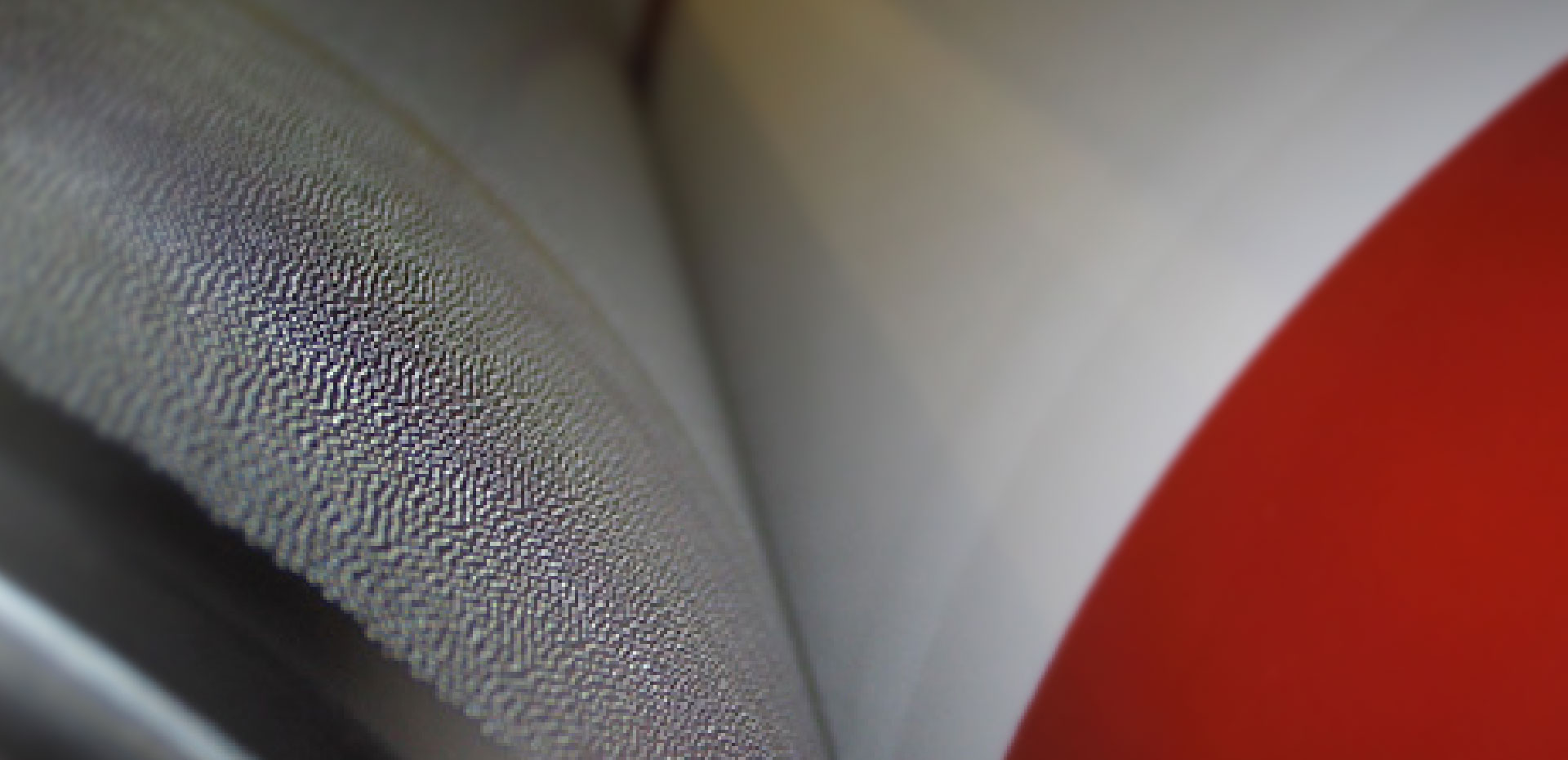

Lamination & Coating

Coatings and laminations cylinders require vast applications, to meet with this BinIqbal is equipped with different rasters Engraving Heads. Stylus geometry and different screening angles can produce mild coats post-printing as well as heavy coats for high bond laminations.

Our Services

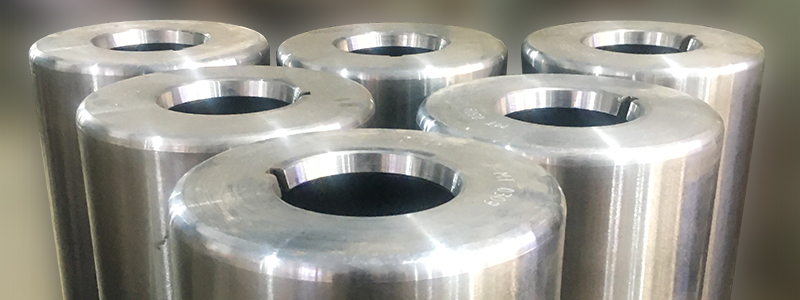

Base Shell

To achieve the best gravure cylinders quality of the base shell plays a vital role. Using high-speed CNC cutting machines and straight of the art Bending solutions, Grinding, and finally, last but not least Dynamic balancing is the core foundation of our product. Sizes up to 1600mm (length) and circumference up to 1500mm are welcome.

Prepress

Having expertise in repro services in our prepress, we are committed to serving our customers.

Image enhancement, Smooth gradients, Sharp text and Color separation combinations(process +spot+pantone+white) help us to get unmatchable results.

delivers calibrated print proof is the key factor

for soft proofing.

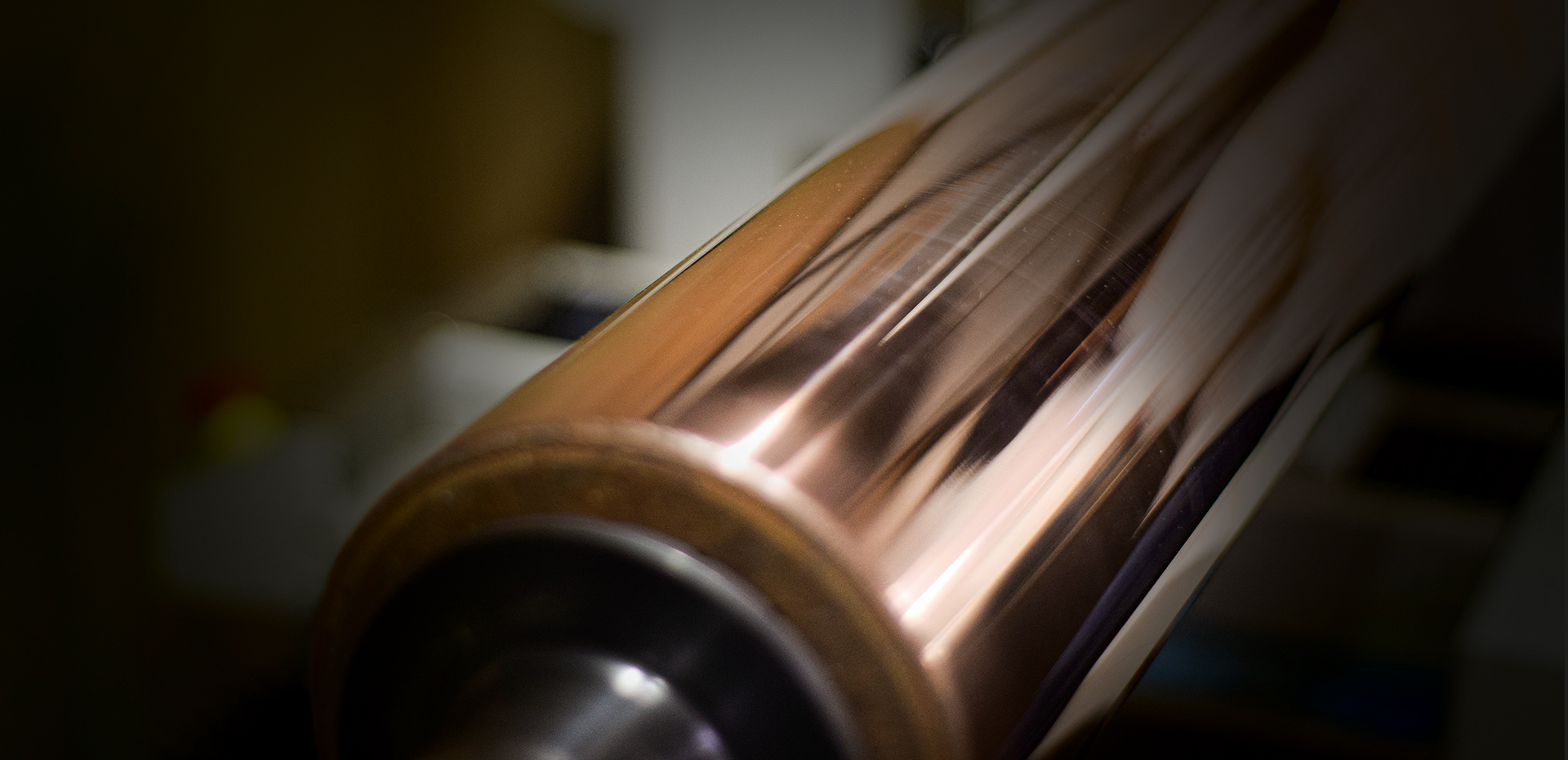

Copper Plating

Copper Plating is very crucial part of the Roto Gravure Cylinder making process, having good hardness, fine ductile copper surface is most important part of it, Biniqal have the High speed automated nickel, copper plating line for their product resulting smooth and sharp engraving.

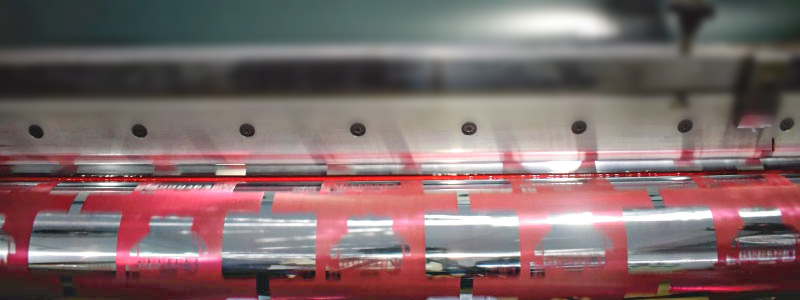

Polish Finishing

Polishing or Finishing is most important part of the process, to maintain smooth surface for engraving, state of the art Grinding and Polishing machine has been added to our fleet, Picture of Grinding and Polishing (Copper and Chrome)

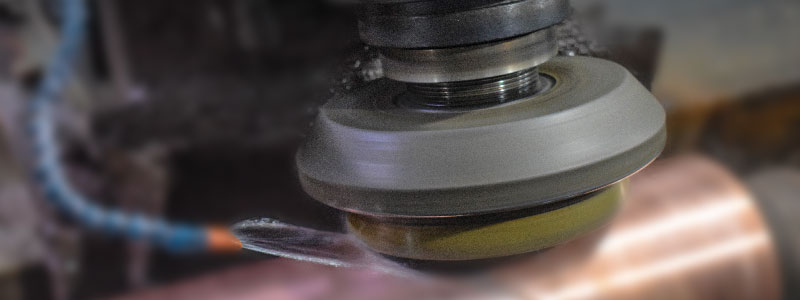

Engraving

Hell Engraving Machines K500 Classic and K2 series at 8khz and 5khz allow us to perform features like Customized Gradations, Free Screening/Angles, Combine Engraving. In result we generate desired need of following target market.

Chrome Plating

Chrome Plating of Engraved Cylinder gives solidity to engraved copper surface to withstand the aggression of ink, chemical & Doctor blade corrision. The optimum micro cracks ensures easy Doctor blade lubrication for long life of Cylinders

Proofing

The engraved cylinders are subsequently proofed to verify engraving authenticity on actual substrate proof with H/T images and exact colur scheme for customers final approval. We also pvide in dilution , lab value of proofed image.

Our Team

We believe that the best team is our asset so we select our team member very keenly, having said that with highly skilled and aligned team player we bring customer’s raw thought into reality. Here are a brief introduction of our key players.

Bilal Chipa

Leader

Having more than 25 years experience of Roto Gravure Cylinders manufacturing. ... Formerly he has been part of "The Engraverz" for 8+ Years as Company Director, he has played major role in developing the company. Later on he quit from the position and stablished Biniqbal Gravure Services.Read more

Proud To Be Associated With